Chemical Engineering Process Flow Diagram Software Free Download

Jun 18, 2012 Software to Create Flow Diagrams CJ711 (Chemical) (OP). To put together a Process Flow diagram, or a modified P&I, quickly. RE: Software to Create Flow Diagrams TD2K (Chemical) 16 May 12 23:36. I am very good with software, lousy with free-hand. I can work faster, probably more accurately, with good software. Chemical engineering flow chart symbols How to read piping. Flow Diagram Software Process Flow Chart Software Free Process Flowchart Free.

Types of Engineering Diagram

Generally, engineering diagrams include electrical schematics; digital and analog logic, circuit and wiring schematics and diagrams; power systems diagrams; maintenance and repair diagrams for electronics and electrical engineering, Process Flow, Piping & Instrumentation Diagrams for chemical and process engineering, the Part and Assembly, Pneumatic and Hydraulic Systems Drawings for mechanical engineering.

Engineering Diagram Software

Edraw is a powerful engineering diagram maker that helps to visualize industrial systems in electronics, electrical, chemical, process, and mechanical engineering. Its objective is to visually communicate concepts, architecture and design of complicated industrial engineering systems to simplify and ease the understanding, analysis and presentation.

Who Can Benefit from the Solution

Since Edraw's purpose is to draw diagrams and drawings to visually present, analyze and report the production cycles, industrial processes and technological systems, industrial projects and R&D. The following people will greatly benefit from it. It is intended for: industrial engineers, production managers, researchers and developers.

Features of Edraw Engineering Diagram Software

STREAMLINED SOFTWARE: Engineering diagrams are used in designing and updating chemical or plant process. David laser scanner 3 keygen generator execution. Engineers and technicians will appreciate Edraw's streamlined P&ID, PFD and electrical software. Drag-and-drop simplicity, keyboard shortcuts, and interactive elements make Edraw the perfect engineering diagram creator.

SMART SHAPES: Each shape is designed with the end user in mind. Our team has added detailed diagramming options for fast, precise drawing. And since Edraw's symbols are vector-based, your P&IDs will be outstanding in any professional context.

FREE EXAMPLES: Whether you're working on your own or with a team, Edraw is the right engineering software for you. With smart shapes and an intuitive drag-and-drop interface, you can build complex diagrams in the fastest way. No drawing skill or experience is required. The 100% integration with MS programs enables seamless collaboration with others. You can transform your engineering diagrams into 18 formats.

Engineering Diagram Symbols

As mentioned above, Edraw's symbols for engineering diagram are all designed for easy creation. They are smart shapes that know how to act according to users' demand. Some of them have floating action buttons and control handles that allow instant change of the shape. You can change one shape into various styles by just clicking the floating button. All shapes are designed with connection buttons so that auto connection can be gained. See some symbols below.

Engineering Diagram Examples

Getting started from examples is the quickest way to draw engineering diagrams. For users' ease, many ready-made examples are offered. These examples can be used directly or with some minor changes. They are editable, printable and sharable for free.

To test out our premium P&ID software with a free 30-day trial, just click on the following button.

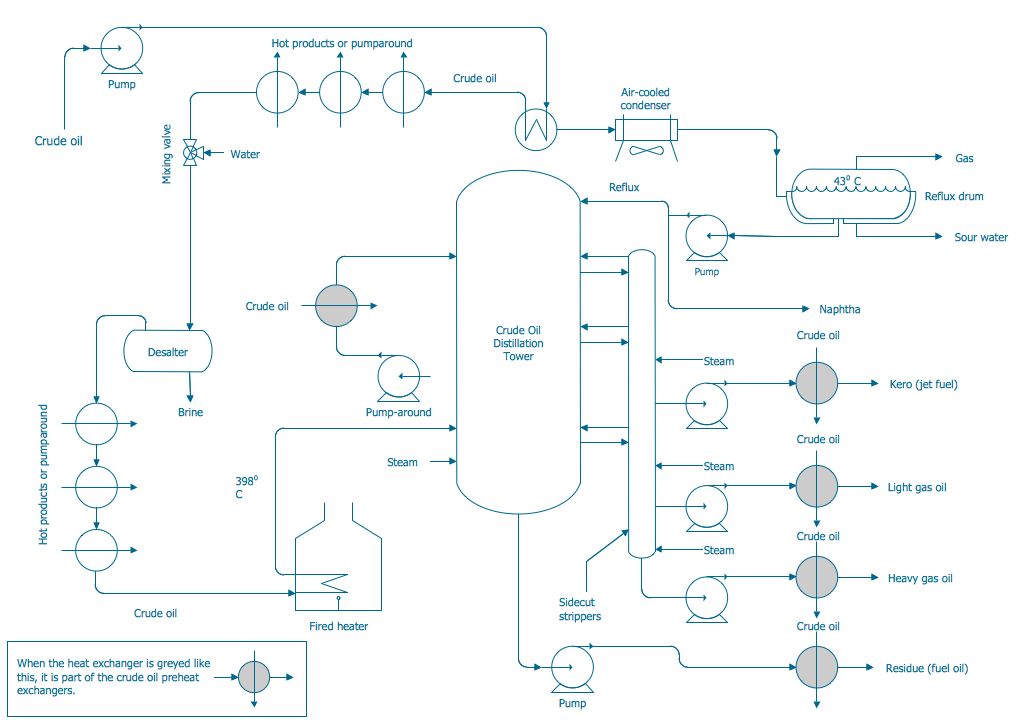

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. Fallout new vegas ammo and condition checking. The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations.[1] Another commonly used term for a PFD is a flowsheet.

Typical content of a process flow diagram[edit]

Typically, process flow diagrams of a single unit process will include the following:

- Process piping

- Major equipment items

- Connections with other systems

- Major bypass and recirculation (recycle) streams

- Operational data (temperature, pressure, mass flow rate, density, etc.), often by stream references to a mass balance.

- Process stream names

Process flow diagrams generally do not include:

- Pipe classes or piping line numbers

- Instrumentation details

- Minor bypass lines

- Instrumentation

- Controllers like Level Control or Flow Control

- Isolation and shutoff valves

- Maintenance vents and drains

- Relief and safety valves

Process flow diagrams of multiple process units within a large industrial plant will usually contain less detail and may be called block flow diagrams or schematic flow diagrams.

Process flow diagram examples[edit]

The process flow diagram below depicts a single chemical engineering unit process known as an amine treating plant:

Multiple process units within an industrial plant[edit]

The process flow diagram below is an example of a schematic or block flow diagram and depicts the various unit processes within a typical oil refinery:

Other items of interest[edit]

A PFD can be computer generated from process simulators (see List of Chemical Process Simulators), CAD packages, or flow chart software using a library of chemical engineering symbols. Rules and symbols are available from standardization organizations such as DIN, ISO or ANSI. Often PFDs are produced on large sheets of paper.

PFDs of many commercial processes can be found in the literature, specifically in encyclopedias of chemical technology, although some might be outdated. To find recent ones, patent databases such as those available from the United States Patent and Trademark Office can be useful.

Standards[edit]

- ISO 15519-1:2010(en): Specification for diagrams for process industry — Part 1: General rules

- ISO 15519-2:2015(en) :Specifications for diagrams for process industry — Part 2: Measurement and control

- ISO 10628-1:2014(en): Diagrams for the chemical and petrochemical industry — Part 1: Specification of diagrams

- ISO 10628-2:2012(en): Diagrams for the chemical and petrochemical industry — Part 2: Graphical symbols

- ANSI Y32.11: Graphical Symbols For Process Flow Diagrams (withdrawn 2003)

- SAA AS 1109: Graphical Symbols For Process Flow Diagrams For The Food Industry

See also[edit]

- Piping and instrumentation diagram (P&ID)

References[edit]

- ^https://www.sciencedirect.com/topics/earth-and-planetary-sciences/flowsheets

Further reading[edit]

- Raymond E. Kirk & Donald F. Othmer (2001). Kirk-Othmer Encyclopedia of Chemical Technology (4th ed.). Wiley-Interscience. ISBN0471419613.

- M.S. Ray & M.G. Sneesby (1998). Chemical Engineering Design Project: A Case Study Approach (2nd ed.). Gordan and Breach Science Publishers. ISBN9056991361.

- R. Turton; R.C. Bailie; W.B. Whiting; J.S. Shaeiwitz (2002). Analysis, Synthesis, and Design of Chemical Processes (2nd ed.). Prentice Hall. ISBN0-13-064792-6.

- Fritz Ullmann (2002). Ullman's Encyclopedia of Industrial Chemistry (6th ed.). Wiley-VCH. ISBN3-527-30385-5.

- Srikumar Koyikkal (2013). Chemical Process Technology and Simulation (1st ed.). Prentice Hall India. ISBN978-81-203-4709-0.

External links[edit]

| Wikimedia Commons has media related to Process flow diagrams. |

- Simplified process flowsheets and flow diagrams of process industries. Development of new integration methods and model flow diagrams.